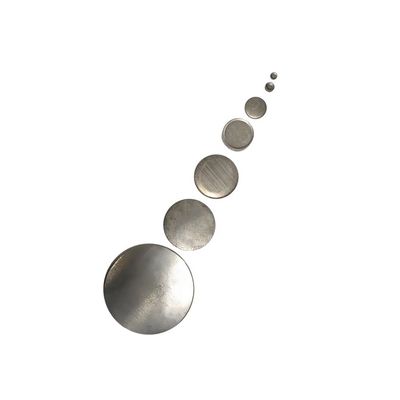

1000 Series High Purity Aluminum Pellets for Manufacturing 20mm Rectangular Slugs

Product Details:

| Place of Origin: | Shanghai, China |

| Brand Name: | Dingnuo |

| Model Number: | 1070 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000 kilograms |

|---|---|

| Price: | $2.10 - $3.00/kilograms |

| Packaging Details: | Use self-propelled winding machine to pack products and place the desiccant to avoid moisture. |

| Supply Ability: | 2800 Ton/Tons per Month |

|

Detail Information |

|||

| Application: | Tubes,packaging Solutions | Surface Treatment: | Tumbled/Sand Blasted |

|---|---|---|---|

| Grade: | 1000 Series | Alloy Or Not: | Non-Alloy |

| Al Content (%): | 99.7% | Powder Or Not: | Non-powder |

| Tolerance: | ±1% | Processing Service: | Punching, Customized |

| Delivery Time: | 22-30 Days | Product Name: | Aluminum Slug |

| Shape: | Flat,domed,conical,rectangular Etc | Hole: | With Hole Or Without Hole |

| Hardness: | H/O | Thickness: | 2mm-40mm |

| Diameter: | 4mm-150mm | Size: | Customized Sizes |

| Color: | Silver White | Type: | 1070 |

| MOQ: | 1Ton | ||

Product Description

Products Description

Raw material 99.7% pure aluminum slugs

Product Name | 1070 aluminum slug |

Color | silver |

Material | ultra-pure aluminium |

Al Content (%) | ≥99.7% |

Alloy Grade | 1070 |

Temper | O/H |

Annealing Temper | 450-460℃ |

Thickness | 2mm-40mm |

Diameter | 4mm-150mm |

Tensile Strength | (MPa)≥75 |

Dffset yield Strength | (MPa)≥35 |

Surface | Tumbled or Sand blasted or as customer requirement |

Shape | Flat, domed, conical, rectangular, etc. |

Hole | With hole or without hole |

Hardness | 16-21HB |

Material Quality | Tension level, Flat, Free of defects like oil stain, roll Marks, waves, dents, scrath, etc. |

Application | 1. packing solutions for daily chemical, machinery, electronics and other fields: e.g. aluminum bottles for food, cosmetics, pharmaceutical, toothpaste, etc. and aerosol cans for deodorants, perfume, cosmetics, hair care, household products, etc. 2. capacitor: household and industrial capacitor, capacitor with stud and without stud. 3. automotive industry: components for motor vehicles, air conditioning technology, plants and electrical engineering. |

Package | PE bag+cartons+wood pallet pallet weight:1000~1125kg carton weight: 25kg 20ft container: 25 Ton max |

Our Advantages

1. Automatic mechanical stamping equipment with CNC servo feeding unit ensure high precision and high stability of products.

2.Stamping dies of imported material ensure high stamping roundness and smooth stamping surface.

3. Imported roundness tester are used to detect the roundness of finished products to ensure that the product accuracy is controlled by +0.01mm.

Application

Products are widely used in auto parts,electronics, food, medicine, cosmetics, personal care and other fields, aluminum slugs are silver metal products, it has very good corrosion resistance, and is the main raw materials made of other aluminum products, in the current production, has a very excellent practicality.

Company Profile

Shanghai Dingnuo Metal Technology Co., Ltd. is a company which develops and manufactures quality aluminum items. We produce a variety of commonly used specifications and series of aluminum slugs (diameter 2mm-160mm, thickness 1.5-40mm). The products are widely used in packaging industry, electronics,medicine, food and automobile industry and other fields.

Our company introduces international leading production equipment, adopts advanced wheel casting and extrusion technology, greatly improves the plastic deformation ability of aluminum, so as to meet the various needs of customers for high-quality products. We can independently complete all processes from continuous casting and rolling, casting rod, extrusion, cold rolling, punching, finishing, annealing, inspection, packaging, storage and transportation. We serve hundreds of domestic customers, including suppliers of BYD, a well-known domestic automobile brand,and PROYA, a well-known makeup brand.

The company has a perfect marketing system and transport logistics team. To provide global customers with better quality, more professional, more perfect service.

Packing&Logistics

Production Flow

Smelting Purification:

Raw materials go through smelting, slag scraping, purification and other processes. The furnace adopts American integral pouring technology, along with the electromagnetic stirring, to ensure pure and homogeneous aluminum water.

Degassing filter :

Imported ceramic filter plate and double graphite rotor degassing device are used to control liquid aluminum to achieve the high purity of double zero aluminum foil.

Punching and cutting:

The automatic high speed punching machine is used to punch the aluminum rolls into round sheets. The mould is a manufactured by imported jig grinder and tested by imported roundness measuring instruments, with the precision error of the products at +0.01mm, equipped with fully automated feeding equipment to ensure high precision and stability of the product.

Annealing:

After stamping, the product is treated by homogenizing furnace to remove stress.

Grinding:

Three-dimensional vibration grinding machine achieves uniform grinding effect and high efficiency.

Shot Peening:

High-end shot Peening equipment and the use of imported aluminum sand make aluminum wafer achieve moderate surface treatment effect.

Degassing filter :

Imported ceramic filter plate and double graphite rotor degassing device are used to control liquid aluminum to achieve the high purity of double zero aluminum foil.

Punching and cutting:

The automatic high speed punching machine is used to punch the aluminum rolls into round sheets. The mould is a manufactured by imported jig grinder and tested by imported roundness measuring instruments, with the precision error of the products at +0.01mm, equipped with fully automated feeding equipment to ensure high precision and stability of the product.

Annealing:

After stamping, the product is treated by homogenizing furnace to remove stress.

Grinding:

Three-dimensional vibration grinding machine achieves uniform grinding effect and high efficiency.

Shot Peening:

High-end shot Peening equipment and the use of imported aluminum sand make aluminum wafer achieve moderate surface treatment effect.

Contact us

Lindsay Li

Shanghai Dingnuo Metal Technology Co.,Ltd.

Adress:Jiading District,Shanghai

Tel/WhatsApp:+86 15300557807/+86 18117214986

WeChat:+86 15300557807

E-mail:sh_dingnuo.metal@outlook.com

FAQ

Q: Are you a trading companyor a manufacturer?

A: We integrate industry and trade. Q: Is ODM&OEM supported? A:Yes.ODM&OEMis supportedPlease be free to contact us and provide the product specifica tions you need. Q: Do you provide free samples? A: Yes,we provide free samples and only the delivery fee will be charged Q: How long is the delivery time? A:Generally the production will be finished within 30 daysand it depends on the quantity and shipping day. Q: Is proofing order supported for customized products? A: Yesproofing order is supportedbut there is a proofing feewhich can be refunded if the final purchase order reaches the certain amount. Q: Is printing supported? A: Yes,for products of aluminum tubesboxesbottles and aerosol cansCMYKfour-color print- ing,spot color printingwhitening printingvarnish printingferrous printing and matte printing is supported.

Want to Know more details about this product